Drink Me

Prototyping

2024

Ceramics

Wheel

What if HF Coors had a ceramic barware collection?

Coors

Porcelain Co.

1920

Coors

Ceramics

1986

HF Coors China Company

1925

Coorstek

2000

Herold expirimented with local clay deposits, which were known to withstand high temperatures, to produce porcelain labware, dinnerware and art.

Herman F. Coors became manager in 1916 after the company started to produce chemical lab ware. During the Prohibition, Coors Porcelain kept the brewery afloat with fine china and cookware.

He left in 1925 to start H.F. Coors China Company, which continues to manufacture dishware for restaurants and institutions to this day.

John

Herold

John Herold was a trained German ceramicist who immigrated to USA in the 1890s.

He founded the Herold China & Pottery Company in 1910 with help from Adolph Coors, who provided a building in Colorado (formerly the Colorado Glass Works) for ceramic production.

Herold China &

Pottery Company

1910

https://www.coorstek.com/en/about/history/

Dinnerware

R&D

Benefits of

Ceramic dinnerware:

Durable and wear-resistant

Has good chemical resistance

Has a high thermal insulation

Ceramic

barware could:

Withstand mixing

Be reistant to liquids of different ph

Can maintain temperature longer

Piece List

I sketched my planned pieces and refined them to be cohesive as a set. I wanted to make 3 types of glassware, a carafe, a mixing glass, a measuring jigger, a muddler and 2 rimming dishes with a juicer.

Vibe Check

Fantastical

Elegant

+

+

Functional

Throwing

Greenware

I made a production plan to keep track of my timeline so I could accomplish the throwing, trimming, drying and glazing of my collection in 4 weeks.

Trimming

Shrinkage

I calculated the porcelain's shrinkage rate and used a shrinkage bar to determine the clay needed for each piece before firing to its final size.

Stemware

This was definitely the most challenging part because I wanted to replicate thin stemware that is usually made of glass out of porcelain.

The stems had to be trimmed in stages so it wouldn’t be sheared off. I really tested its limits to achieve as skinny of a stem with my abilities.

Attaching

To minimize damage while drying, I brushed wax on the joints and wrapped the pieces tight to dry them slowly.

Oops! Too dry!

Bisqueware

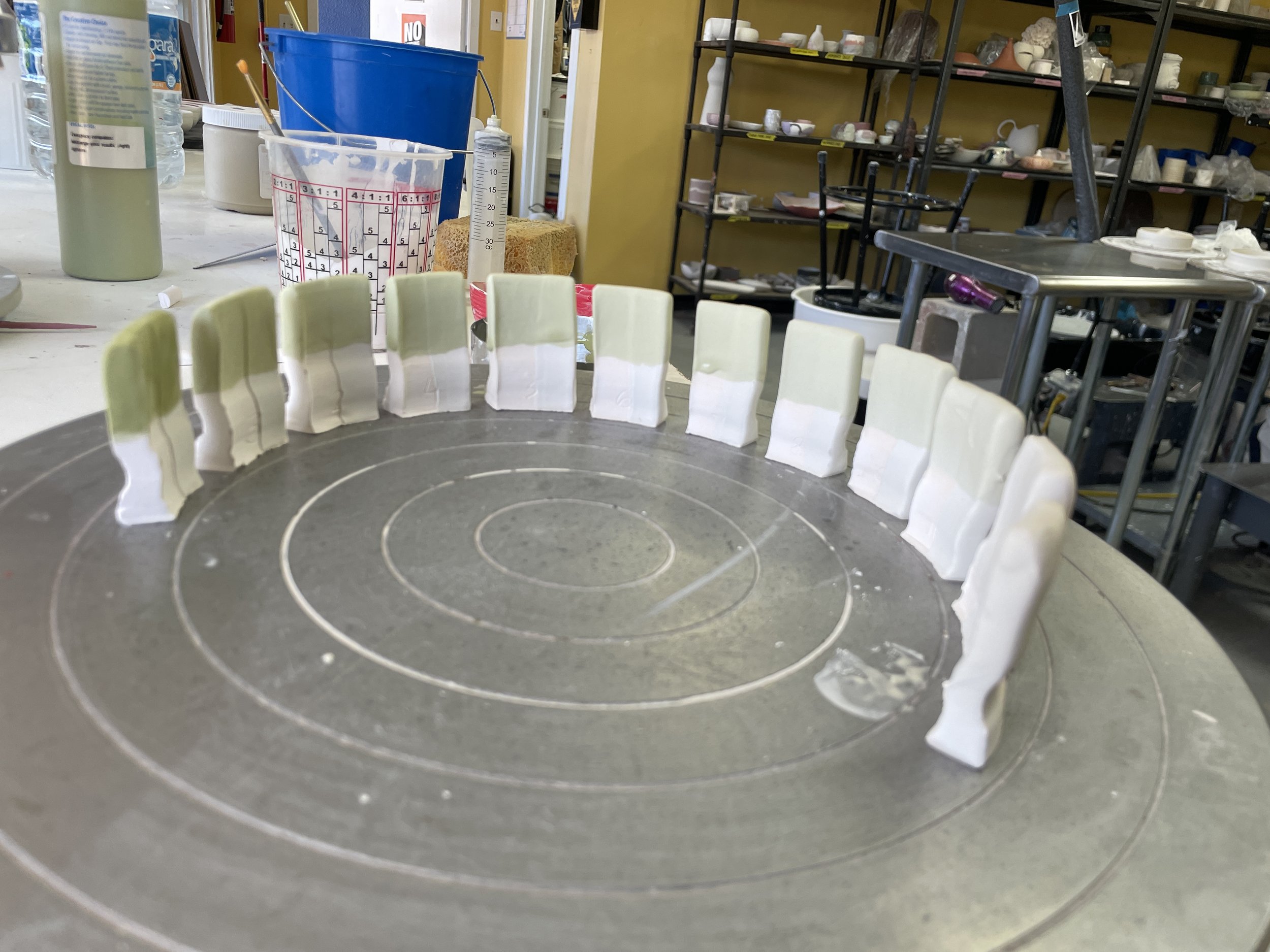

Glazing

The idea was to create a gradient from green to white across the collection (very Pincus inspired).

I couldn’t decide on how I wanted to glaze my collection so I made digital mockups to help me visualize what it could look like.

Something I didn’t know could be an issue was pyroplasticity during the glaze firing. The weight of the drinkware caused the stem to lean over, giving more Alice in Wonderland than Elvish elegance. Maybe a different kiln setup could prevent this issue.

Glazed

↓

Fired